People often think it’s just a new buzzword for recycling.

But it’s much more than that. It’s the best tool we have for tackling the climate and biodiversity emergencies, at the same time making sure we all have access to the resources, food and services we need for a healthy, enjoyable life.

Lots of business leaders, governments, researchers and consultancies are investing in this. Circular products, materials and business start-ups are popping up, disrupting business as usual with future-fit solutions that are better for people, planet and profits.

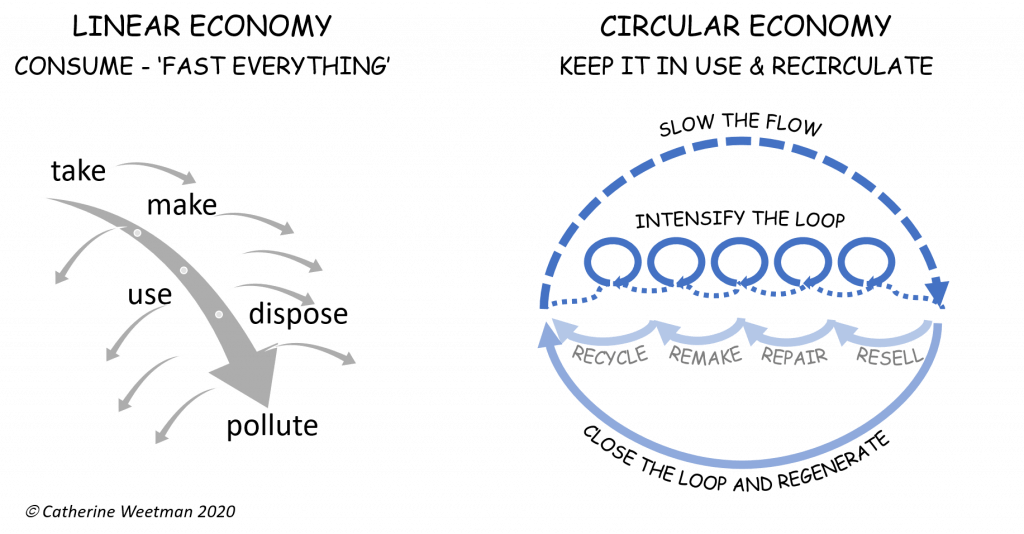

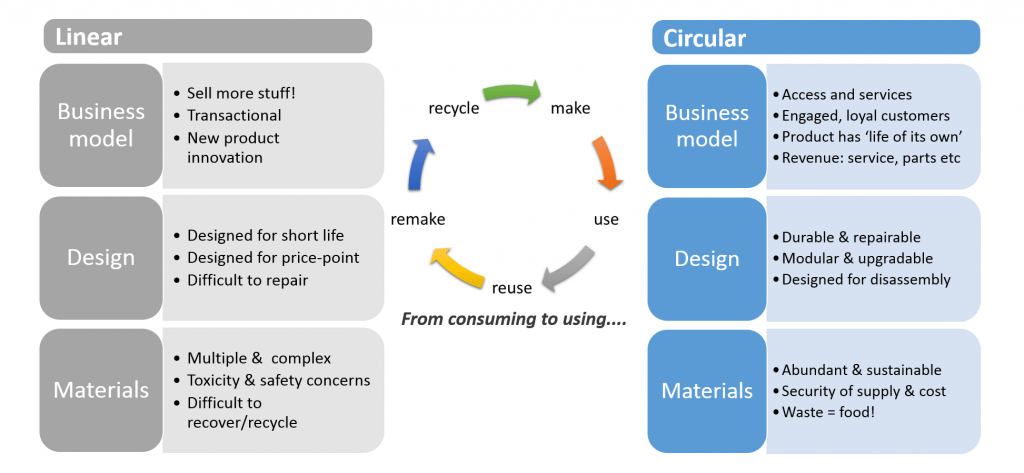

So what is the circular economy? Probably the easiest way to start thinking about it is to contrast it with how our industrial economy works now. We take some materials, make something, use it and then discard it – take, make, waste. That’s a linear system, consuming and depleting resources and creating waste and pollution.

Adopting circular economy approaches would mean we can have enough, for all of us, forever.

The Circular Economy aims to keep products, components and materials in use for longer, and reuse them, so we get more value (usefulness, or productivity) from them. In a circular economy, all ‘waste’ becomes ‘food’: either for another industrial process; or for nature. We also need to regenerate, so we have sustainable flows of both finite and renewable resources into the future.

New materials, scientific advances and recent technology developments mean circular business can be more resilient, competitive and prosperous.

Read on if you want to explore:

- Why is the circular economy important?

- Circular economy principles

- Circular strategies – a clear purpose

- Circular business models – a fundamental shift from consuming to using

- Components of a circular economy

- Circular economy business benefits – how does it help you succeed and prosper?

- What do we mean by the ‘linear economy’?

Do you want to learn more about the circular economy, and how it can strengthen your business?

Why is the circular economy important?

What’s wrong with the way we do things now? Why do we need a different approach to business?

Why do we need a different approach to business? ‘Traditional’ industrial processes are often called a ‘linear economy‘: meaning we take materials, make something, use it and then dispose of it. This means we are using up finite resources, and using renewable resources faster than they can be regnerated. In addition, we are putting immense pressure on land, water and the living systems we depend on for air to breathe, clean water, healthy soil.

We now know we are causing dangerous climate change by burning fossil fuels, using fertilizers and clearing forests, all of which creates Greenhouse Gas (GHG) emissions. Our world population continues to grow, and people have more money to spend on food, clothing and other stuff. It’s good news that people’s standards of living are improving, but it means we are creating even more demand for those under-pressure resources.

Governments, businesses large and small, NGOs and consultancies are investing in circular economy approaches. The World Economic Forum, McKinsey, the Ellen MacArthur Foundation, the European Union and many other organisations are helping to accelerate the transition from linear to circular, sustainable and prosperous models.

“Businesses that work on the basis of circular principles are amongst the fastest growing in the economy”

Dr Martin R Stuchtey, McKinsey Center for Business and Environment [i]

Massive benefits for global economies

There are widespread savings from reduced material use, efficiencies in production and the supply chain. These lead to lower levels of waste, pollution and GHG emissions. For the European Union, McKinsey and the Ellen MacArthur Foundation estimate 7 per cent growth in GDP (Gross Domestic Product), with potential for up to half a million new jobs.

According to Accenture, “shifting to the circular economy could release $4.5 trillion in new economic potential by 2030“.

Circular economy principles

There isn’t a universal definition of a circular economy – a recent study by Kircherr, Reike and Hekkert found 114 different definitions!

Most schools of thought include these four principles:

- We design products and equipment to be durable and robust, so they stay in use for longer. For the user, this means a better lifetime cost, as robust, repairable products can be rented, or shared, meaning that more people can use fewer products. A rented city bike might be in use for 12 hours a day; compared to your personal bike that you use perhaps once a week.

- Business models encourage the use of products and equipment, instead of ownership. Circular approaches also create markets for new services: for reuse, repair, remanufacturing and recovery of resources.

- We use safe, sustainable materials that are recycled (and recyclable) or renewable.

- After we’ve used them, we recover the products, components and materials. This means they have value: we can use them as a resource for another industrial process, or they can become food for nature – compost!

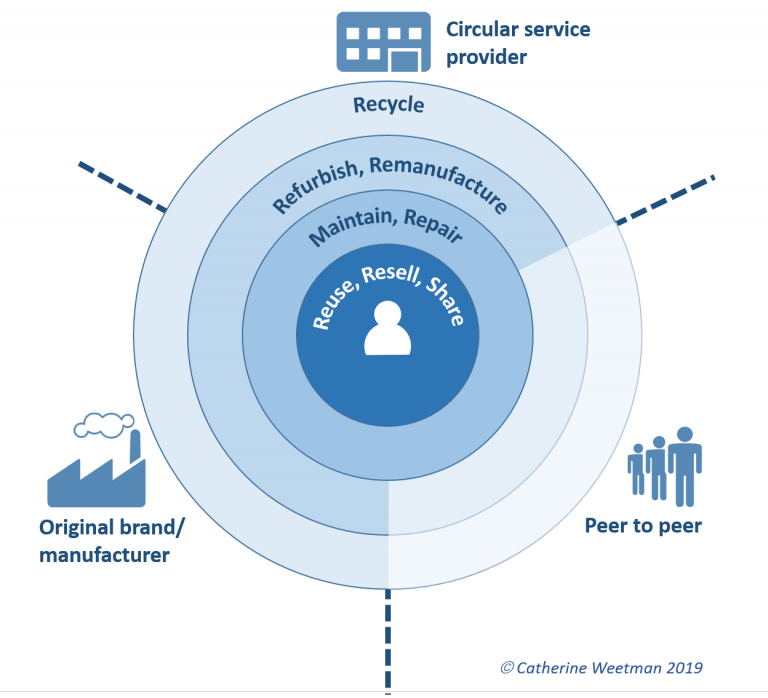

This diagram shows the different ‘loop’ options, starting with the highest priority of sharing and reusing (the inner loop). Recycling (our least preferred option) is the outer circle. Circular flows can be managed by the original brand, by a specialist provider, or between users (peer-to-peer).

Remanufacturing and recycling, however, is more specialist, and therefore more suitable for business, rather than for people to do at home.

New ways of thinking

A range of different perspectives, including systems thinking, biomimicry and planetary boundaries, can help us create new solutions and disrupt existing alternatives.

Business can be a force for good, with a purpose beyond profit. How can we do this?

- By ensuring fair, transparent and shared-value approaches across the supply chain, meaning a good quality of life for everyone involved.

- And by using and regenerating safe, sustainable resources – so we have abundant supplies instead of scarcity.

Circular business strategies – a clear purpose

Business is part of a system; and that the purpose of a business is critically important. As Donella Meadows reminds us, the ‘least obvious part of the system, its function or purpose, is often the most crucial determinant of the system’s behaviour’.[i] She goes on to explain that ‘a change in purpose changes a system profoundly, even if every element and interconnection remains the same.’

Leading circular economy researchers – Nancy Bocken and team[ii], Martin Geissdoerfer and team[iii], John Mulrow and Victoria Santos[iv] – highlight the need for a clear purpose for circular business models, to ensure we have real ‘system value’ for all the stakeholders: business, society and the living world we all depend on. Building on their work, I’ve chosen four goals for circular business models: to slow, intensify, close and narrow the loop.

However, if we think about the global issues, of pollution and waste leading to damaged ecosystems, degraded land and contaminated water, plus the critical need to reduce Greenhouse Gas levels and air pollution, we can see the need to go further. We must design loops and business models for an economy that restores resources, natural systems – and society. We need to go beyond merely closing the loop on resources, by designing regenerative models that restore our damaged ecosystems, clean up pollution and waste and restore health, wellbeing and prosperity to society.

Three circular economy strategies

Circular economy business models should align with those aims. With this in mind, I’ve expanded ‘close the loop’ to include regeneration, to give three circular strategies plus a supporting resource efficiency aim.

- Slow the flow of resources, by making durable, repairable products that are easy to disassemble at the end of use. By using the product and materials over a longer timeframe, we get more value from those materials;

- Intensify the resource loop, by using the product and materials more productively, often through sharing or rental systems. This means we get more ‘usefulness’ and value from those materials;

- Close the loop and regenerate. At the end of use, we recover, sort and process the product and materials, so we can use them again, ideally with minimum intervention (energy, materials, etc). Additionally, because we have been depleting resources and degrading ecosystems, we need to regenerate lost materials, and regenerate soil, land, water and living systems to provide future resources and sustain nature’s services.

- In addition, we can narrow the loop, by reducing consumption of materials, energy and other resources. This ‘resource efficiency’ uses fewer, simpler materials as well as less overall.

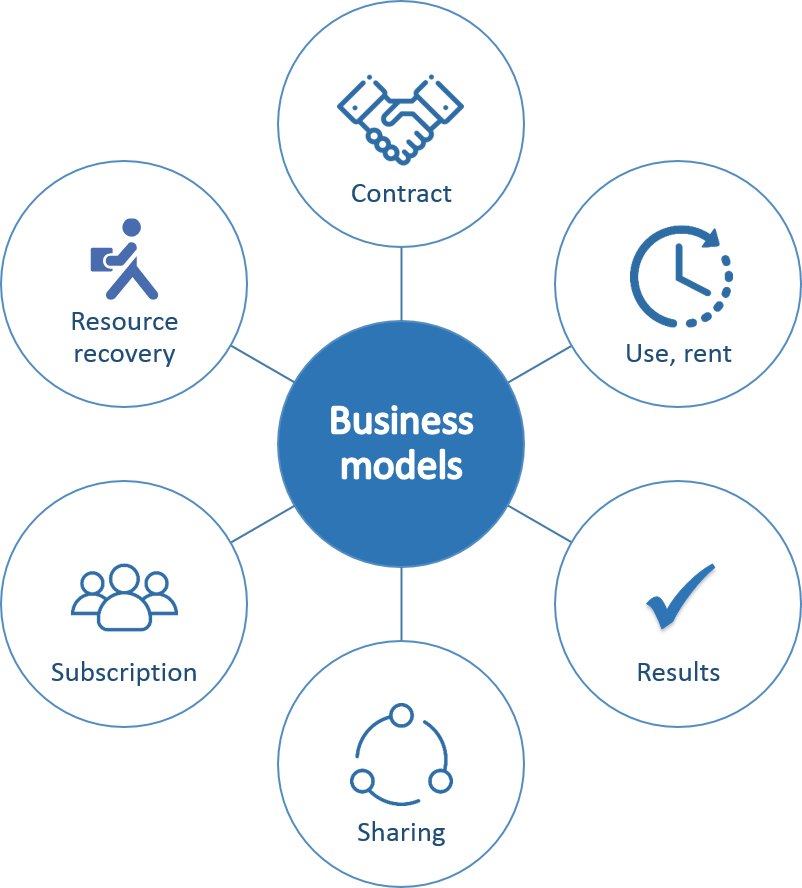

Circular business models – from consuming to using

In the linear system, companies want to sell more. They try to persuade us to buy the latest kit to replace the one that’s broken or no longer supported. This wastes precious resources – and wastes our money! We should question why we want to own stuff that we only use for a few hours each year. Why own it while it depreciates, the performance drops away, or the technology becomes out-of-date: all of which leave us worse off. A couple of examples include a power drill and even a car. Did you know that on average, cars in Europe are idle (ie parked) for 23 hours each day?

The circular economy uses different business models, aiming to encourage use instead of ownership. It’s about helping people to use products for longer, or use them more ‘intensively’. What do we mean by ‘intensively’? Let’s return to our car example (typically used for just one hour each day): an hourly rental system would enable the people to use the car for significantly more hours in a day. We improve the ‘intensity’ of use – in other words, we get more from less.

These business models encourage users to rent; pay for access; buy ‘performance’ of products and equipment, or subscribe to an easily accessible shared service.

This creates new revenue streams and market opportunities for your business.

New ways of thinking

A range of different perspectives – including ecodesign, systems-thinking, and alternative economic models (we like Kate Raworth’s ‘doughnut economics’) – are helping us develop new solutions and disrupt existing alternatives.

Designing circular systems can build a better business (and a better world!).

Ecodesign An approach that aims to minimize the overall environmental impact of a product or service. Ecodesign encourages innovative design solutions that consider the entire lifecycle, from extraction or harvesting of raw materials, through production, distribution and use, all the way to end-of-use recycling, ‘repair-ability’ and disposal.

Systems thinking Systems thinking is the process of understanding how those things which may be regarded as systems influence one another within a complete entity, or larger system. In nature, examples include ecosystems in which various elements such as air, water, movement, plants, and animals work together to survive or perish. In organizations, systems consist of people, structures, and processes that work together.

Source: http://donellameadows.org/systems-thinking-resources/

Business can use circular approaches to be a force for good, with a purpose beyond profit. How do we do this?

- By ensuring fair, transparent and shared-value approaches across the supply chain, providing a good quality of life for everyone involved;

- Through using and regenerating safe, sustainable resources – creating abundant supplies instead of scarcity;

- By designing systems to circulate, share and value resources and regenerate natural systems.

We look at the business benefits later on this page.

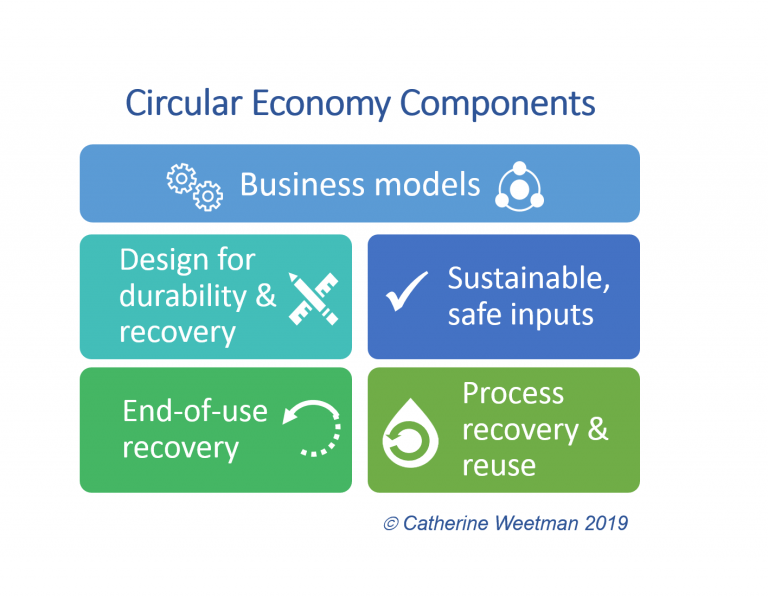

Circular Economy Components

Designing circular systems can build a better business (and a better world). We’ve looked at circular business models, but what else should we do differently?

“waste is only waste if you waste it” will.i.am

(Quote from the DoNation Blog)

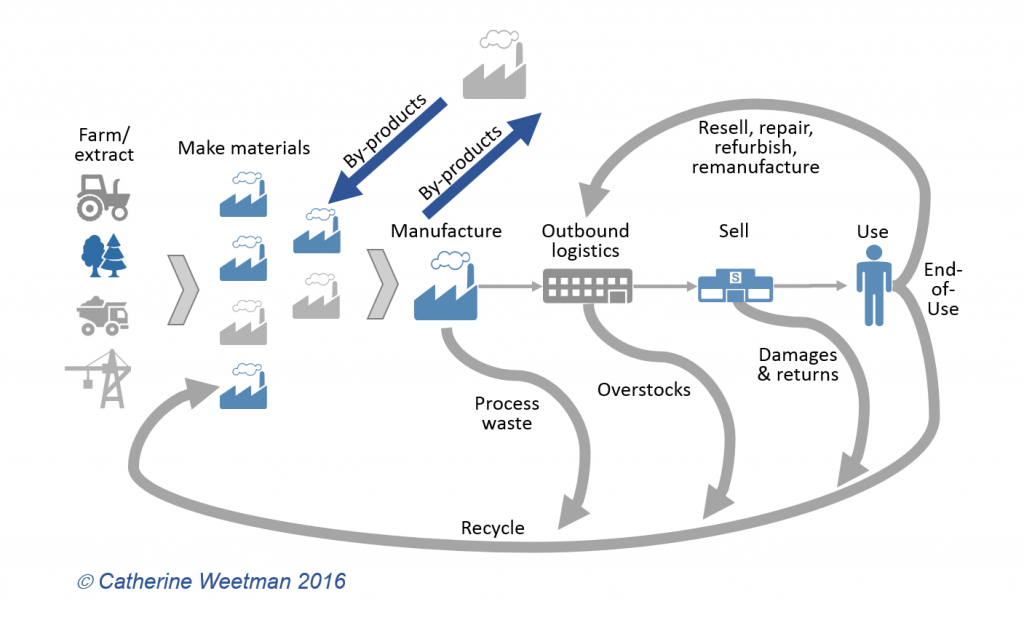

I find it easiest to think about each stage of the business and the supply chain, and think about the places where you can intervene, to make something more circular.

This diagram shows my 5 circular economy components.

You might worry that rethinking your business to ‘close the loop’ completely, creating ‘cradle to cradle’ products, seems overwhelming, or too disruptive.

How can you make it less risky and disruptive? Firstly, you can use an incremental approach to reduce the risks, starting with any of these circular economy components. You might decide to replace a material that’s expensive, or difficult to source. Alternatively, you could offer upgrade or repair services for one of your products.

You can feel more confident by building a solid business case and engaging employees, suppliers, customers and other stakeholders. Similarly, thinking about the bigger system and creating a sensible project plan can avoid ‘unintended consequences’.

Unsurprisingly, learning from your first circular success improves your next project, building confidence across your business as you close the loops.

Circular product design

To begin with, high quality, durable and repairable products improve your customer’s experience. This builds trust in your brand, leading to loyal customers. You’ll benefit from spending less on marketing to find new customers. Selling spare parts and offering repair and refurbishment services means you can create new revenue streams.

- Designing products to be modular means repairs are simpler and cheaper. Modular products make it easy for you to develop and offer upgrades, such as new technology, better functionality, etc. The modular design of the Fairphone 2 mobile phone means the user can swap out any part in a few minutes, needing only a screwdriver.

- Upgradable products are a win-win because the customer gets a better product, and you keep the customer’s business. The Fairphone 2 is upgradable, too.

- Designing products for repair, remaking and recycling creates new, profitable activities and reduces the cost of repair, remaking and recovery. That could mean new service opportunities for you – or your partners. Longer-lasting products have a higher resale value; they build trust in your brand and mean you can sell in markets where people can’t afford the new product.

- Specifying fewer, simpler materials, helps create circular systems too. Avoiding adhesives, bonding, coating and other compounds makes it easier and cheaper to reuse the materials, repeatedly.

- Ensuring all materials are easy to identify, with standard markings where possible, helps encourage recycling and reuse.

Circular inputs = Secure supplies

You can secure your long-term supplies of materials and process inputs, by switching to abundant, renewable or recycled resources, so you can ‘close the loop’. We tend to forget that all material resources have limits:

- Metals, minerals and fossil fuels are finite resources (‘technical resources’ in circular economy terms). Even if the sources seem to be plentiful, issues including trade restrictions and tariffs, by geopolitics, conflict and natural disasters can all affect supplies.

- Food, fibres, timber and other ‘renewable’ materials (‘biological resources’) are also constrained: by water, suitable land, as well as the risks above. If we choose a renewable material, we must ensure it’s produced sustainably and can renew within the intended lifecycle of the product. For example, if we harvest a tree to make five chairs, those chairs should last for as long as it takes a new tree to grow to a harvestable size.

There are increasing concerns about the social and environmental impact of farming, fishing, forestry, mining and material extraction. Over-fishing, deforestation, the use of synthetic pesticides, fertilizers from fossil fuels, intensive irrigation in areas or water scarcity and many other issues are highlighting our dependence on unsustainable material sources.

Resources and materials, for both the product and the process, should be renewable or recycled, so you can be confident of securing supply over the long-term. It’s also critical that all the inputs should be safe for humans and living systems, at every stage of the process.

New materials are appearing, including plastics from abundant materials like algae, ‘leather’ from mushrooms, ‘silk’ from waste citrus peel, and many more.

Circular process design

Designing more circular production processes provides benefits.

Maybe you can recover your own end-of-life products, components and materials. Recoverable resources include energy, chemicals and water, as well as the materials you use to make the product. In addition to reducing costs by recovering your own inputs, you could develop new by-products and thus increase your revenue by selling into new markets.

British Sugar is a great example, creating a wide range of by-products from its production process. Importantly, it recycles waste heat and carbon dioxide from manufacture to grow crops in nearby hothouses too.

Resource efficiency approaches are useful too, helping us focus on using less of everything and thus saving money too.

Recovering end-of-use products, components and materials

Finally, we want to keep products and materials flowing around the system, ideally without losing ‘value’ (and usefulness) for the next cycle. High quality, durable products will have resale value for another ‘use cycle’: perhaps by the user (eg on eBay), by a specialist reseller, or by the manufacturer. In Japan, Patagonia’s clothing may resell at a much higher price than the ‘new’ version!

For example, IKEA noticed that many of its products were for sale on eBay. At first, this was a concern, then IKEA realised this didn’t undermine its core business. Instead, it helped the original consumer feel confident they could resell the product in the future, and thus reinforced the brand value. IKEA decided to support this by providing easy access to commonly used fixings and fasteners, making replacement easy if those small parts are lost during disassembly.

Recovering your products gives you easy access to your own components and materials – and designing for easy disassembly makes it efficient for you to reuse, refurbish or replace them to give another life to the product or the material.

Circular economy business benefits

We’ve looked at the benefits for the economy, but how do you work out the advantages for your business? How can you improve bottom-line growth, and maybe even top-line growth at the expense of your competitors?

There are wide-ranging benefits of ‘closing the loop’ and ‘slowing the flow’ of materials, for business customers and consumers. For example, one advantage of using instead of owning is smoother, more regular cashflow. That can be a big plus for buyers and sellers of high-value products, equipment and infrastructure.

Renting, leasing, sharing and subscription services are attractive for consumers too: it’s already common for cars and phones in some countries, and of course for housing.

Business models for access and service

Those durable, robust product designs are more suitable for renting and sharing. This opens up new opportunities, especially for products that people use infrequently (eg power tools), or in a range of different places (eg city bike and car hire). Those services could help you could grow your business, perhaps by renting a higher quality product at a more affordable price. BMW developed its DriveNow rental service, finding it helped to grow a much bigger customer base.

In a circular system, upgrade options and repair services can keep the product up to date and fully functional for longer. It may even be attractive for the end users to repair and upgrade it themselves.

This means you can sell spare parts, offer repairs and servicing, and even set up specialist remanufacturing and recycling services – maybe with a partner.

The upside is new revenue streams and market opportunities for your business.

Services mean ownership of the product stays with the brand and enables the product to return to the producer after we’ve used it. Having recovered the product, component and materials, the producer can choose to resell, repair, remake or recycle them.

You can save money on materials, energy and process inputs, and reduce waste and harmful emissions. You may be able to convert disposal and waste costs into savings, and new profit streams.

Circular = stronger, deeper customer relationships

Business models providing access to products, instead of ownership, can build closer customer relationships. Regular communication flows help you better understand what they need and how they use your product. You’ll know which parts are likely to degrade or fail first, and how you can improve it.

Circular is better for your customers

Your customers enjoy great quality, reliable products, that are easy to repair and upgrade, thus saving money and the hassle of buying (and getting used to) a new one. Knowing something is repairable (ideally with a strong warranty) means they feel confident about buying your products – and repairing, improving or customising it makes them feel more engaged with it. It means they are more likely to recommend you and stay loyal to your brand.

What do we mean by the ‘linear economy’?

Most modern systems, for products, equipment and infrastructure, follow a similar process. We take some materials, make a product, use it and then discard it.

We extract around 100 billion tons of natural resources, every year, to make what we consume. That’s more than 12 tons for every person on the planet. Based on current trends, that number is likely to double by 2050.

The systems we’ve created are shockingly wasteful. The Circularity Gap report says we recover less than 10 per cent of our resources to make them into new products.

We could call it a throughput economy, or even a ‘waste economy’. This system means we’re trashing our planet, with lots of downsides:

- people feel excluded, fearful and exploited,

- businesses face resource scarcity, higher charges on waste and risk to their reputations,

- ever-increasing Greenhouse Gas emissions are pushing us towards dangerous, irreversible climate change, and

- we are overloading and depleting nature. It’s easy to forget that we depend on living systems that provide critical services for us, including pure air, clean water and healthy soils.

The Global Footprint Network calculates that globally, we’re using the resources of 1.7 planets, every year. When we think about that, it’s easy to see that ‘business as usual’ is not sustainable.

Go back to Why the Circular Economy is Important

References

[1] Meadows, DH; edited by Wright, D (2008) Thinking in Systems: A Primer, Sustainability Institute, published by Chelsea Green Publishing

[ii] Bocken, NMP, de Pauw, I, Bakker, C, van der Grinten, B (2016) Product design and business model strategies for a circular economy, Journal of Industrial and Production Engineering, 33:5, 308-320, dx.doi.org/10.1080/21681015.2016.1172124 [accessed 2 October 2019]

[iii] Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy (2018) J. Cleaner Production, 190, p712–721 www.researchgate.net/publication/324617908_Business_models_and_supply_chains_for_the_circular_economy [accessed 2 October 2019]

[iv] Mulrow, J and Santos, V (2017) Discard Studies [online] discardstudies.com/2017/11/13/moving-the-circular-economy-beyond-alchemy/ [accessed 10 October 2019]

Learn more...

We can help you find out more about the circular economy and how it can strengthen your business. Please get in touch to discuss a private workshop or talk, or chat about our 1-to-1 coaching packages.

In the meantime, have a listen to the Circular Economy Podcast, or buy Catherine’s award-winning book!

We also like this short video from Alex Magnin at Sustainability Illustrated, explaining the circular economy with some examples.